Railway

Mass Transportation

NedTrain, the Dutch railway company, decided to launch a vast refurbishment programme of its 81 double decker regional train sets, after nearly 20 years of services. Together with Ultimate Europe, Vitalo was selected to supply the interior panels.

OEM Key requirements

- Keep costs low

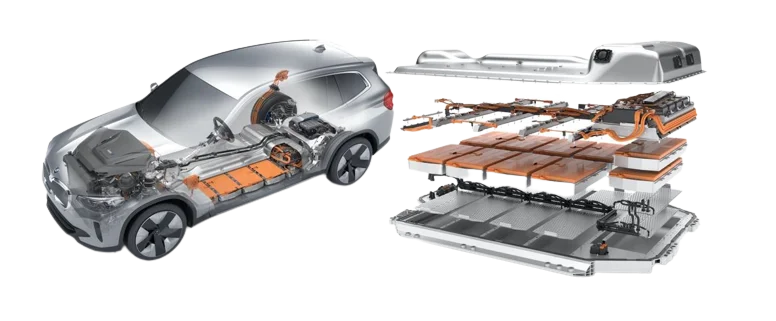

- Reduce weight in order to save energy costs and ease assembly

- Improve passenger's perception of quality and comfort

- Provide vandal proof materials

- Ensure flawless supply chain of the refurbishing lines in order to keep costs down and pace up

The Vitalo Group response : a Vitalo solution

- Re-design by Vitalo and Ultimate in order to provide plug-and-play assembly compatible with pre-existing fixation system

- Organise Just-in-Sequence delivery

- 45% weight reduction over composites interiors

- Anti-graffiti material